Those most commonly used are the minus pins.

Pin gage set plus or minus.

Likewise a plus pin gauge set includes pins with a specified tolerance above the target dimension creating a no go situation for a bore at the target dimension.

If you re looking for a cheap passing grade quality set try enco.

These can be either plus or minus pins.

Plug and pin gages are used to compare hole and slot dimensions or locations to specific tolerances.

Enco has free shipping promotions regularly.

Tolerance is normally 0002 0000 for zz plus gages and the opposite for minus.

I need to do some interference fits 1 4 for example.

There are several basic types of products.

Every pin that i have checked has been 0002 undersize or oversize but that is not a universal given.

A minus pin gauge set includes pins with a specified tolerance below the target size allowing the pin to fit within the target dimension.

If super accuracy is required pin gages are available in 0001 increments.

Fwiw the minus sets are more common and slightly less expensive in general.

Set micrometers verniers and other measuring devices.

However plus minus pin gage sets each have their utility i think it s probably a wash.

It is common practice in american industry to use a go nogo pin set up.

Measure hole diameters calculatedistances between holes gageslot widths and locations.

They are tolerance up to 0002.

It takes a minus to fit in a hole the size marked on the pin.

Go gages and no go gages are fixed limit gages with gauging limits based on the plus or minus tolerances of inspected parts.

There are shars to starret to meyer in terms of cost and i assume quality.

Therefore a 9998 gauge pin might be actual size but it is generally referred to as a 1 000 pin the size shown on the pin.

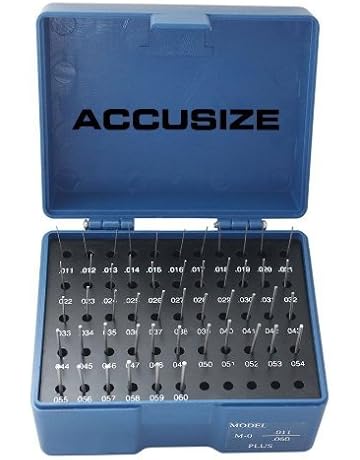

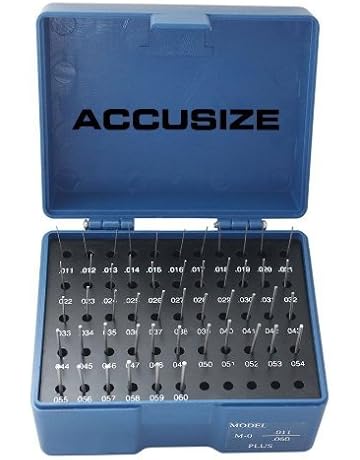

All gages are uniformly 2 long with ground ends allowing you to use both ends for increased gage life.

Steel class zz gage pins sets.

Eric m liked this post.

I took a quick look at availability and there are plus sets and minus sets.

Uses for precision go nogo measuring of hole sizes and depths checking hole location and distance and setting micrometers.

Gages are carbon chrome alloy steel grade 52100 bearing quality steel and heat treated to a 60 62 rockwell c hardness.

Make quick and accurate measurements with vermont gage pin gages.

Which would you buy minus or.

I want some pin gages to measure small holes.

Use for go nogo inspection.

Minus pin gages normally found in sets can be anywhere between 0002 undersize to the nominal dimension and plus pin gages anywhere between nominal and 0002 oversize.

Go gage dimensions are based on.

Class zz 0002 or 0 005mm tolerance go plus or nogo minus.